H2 Turbo Technology is an industry-leading developer of mechanically driven, turbochargers (“SuperTurbos”) that allow for precise air control, optimized engine performance and reduced emissions for Class 4-8 hydrogen internal combustion engine (“H2 ICE”).

SuperTurbo technology is patent-protected and is a key enabling technology for hydrogen internal combustion engines, which are being developed as a potential alternative to traditional internal combustion engines that produce CO2 and other harmful emissions.

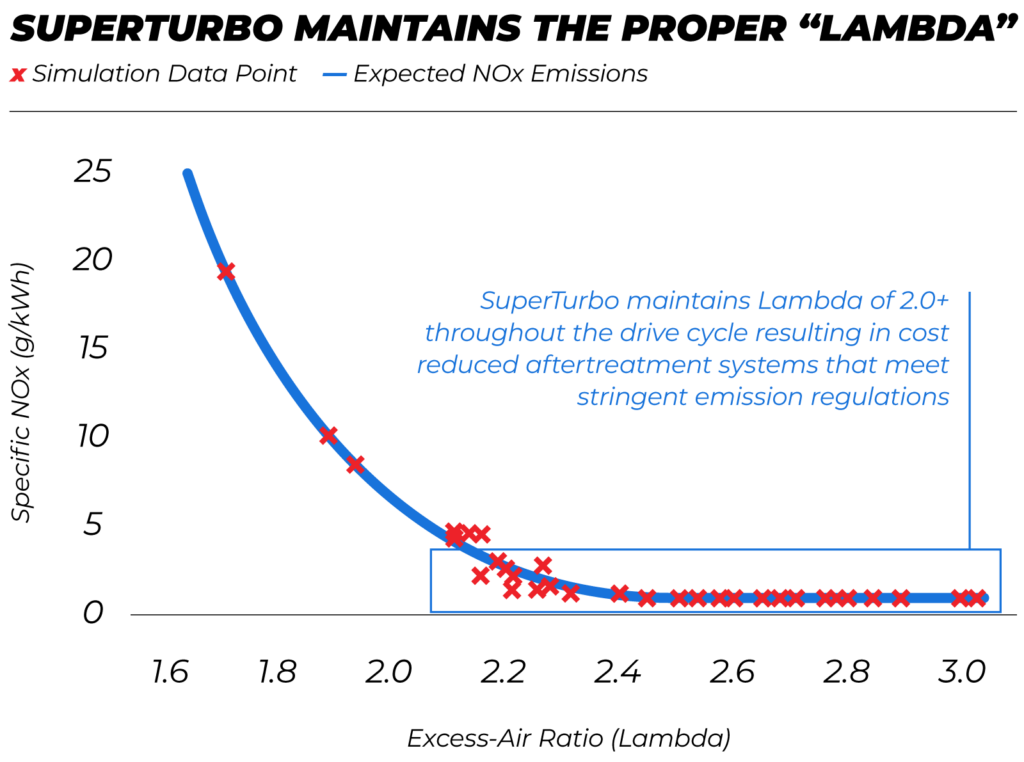

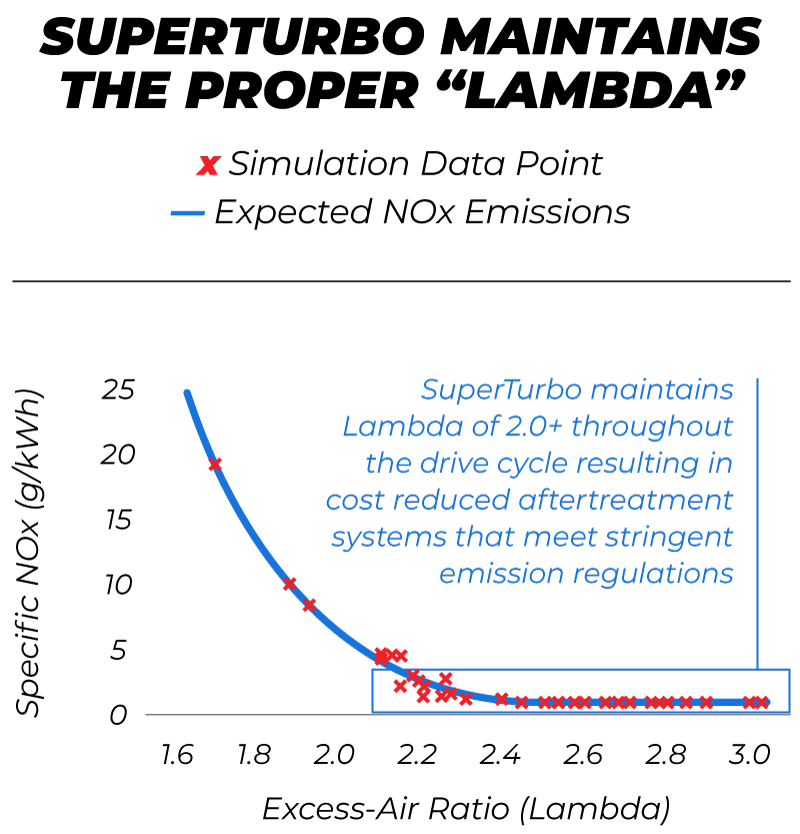

AVL Simulations-Independent Performance Simulations

on a Hydrogen Internal Combustion Engine

HTT partnered with AVL which is the world’s largest independent company for the development, simulation and testing of powertrain systems

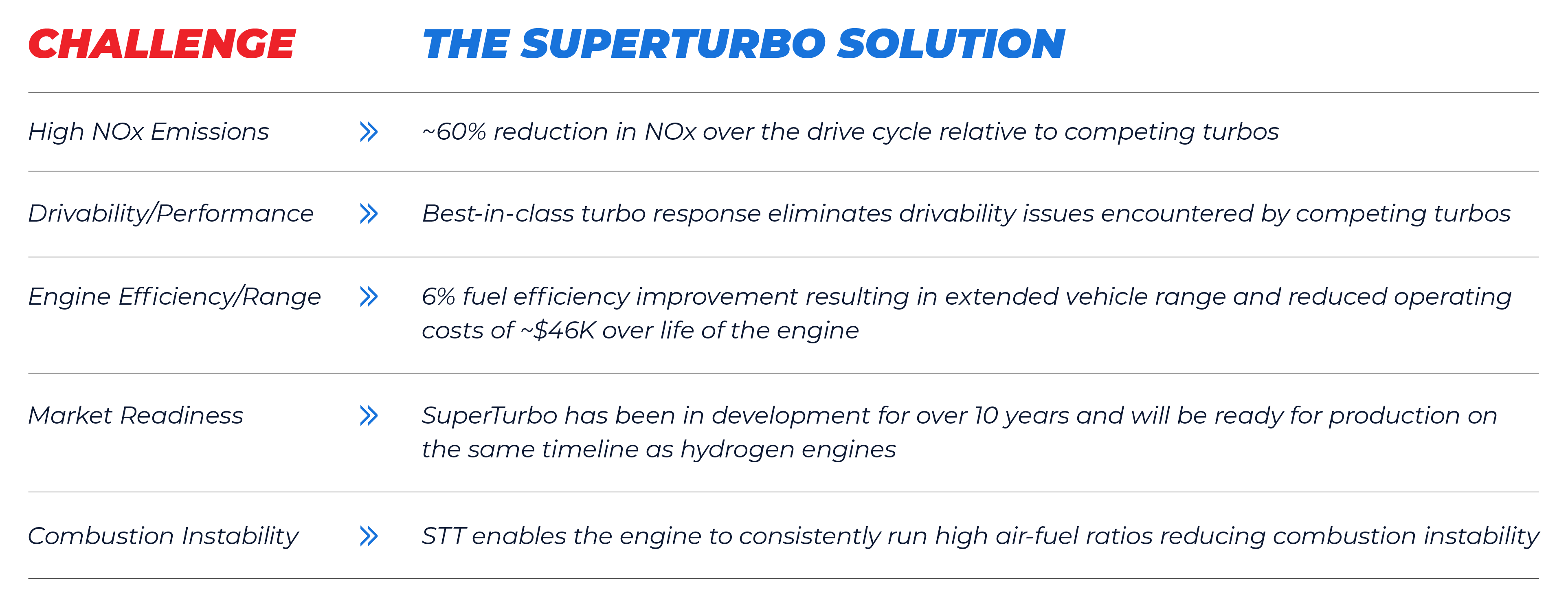

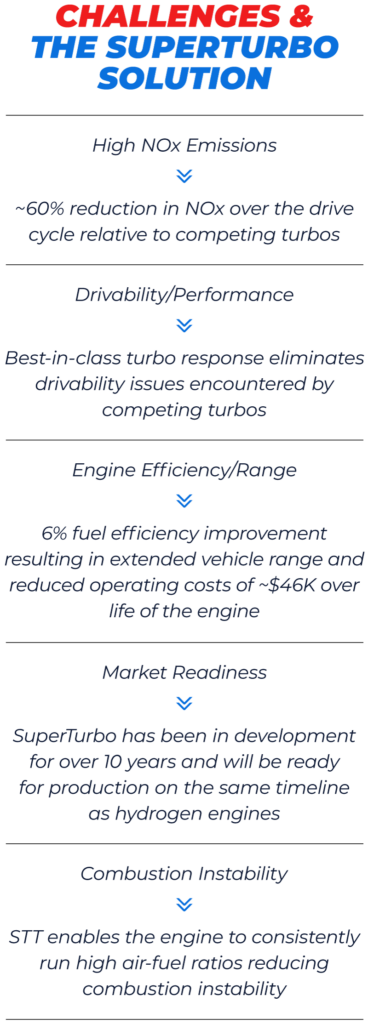

Simulations on a 13L hydrogen engine using the SuperTurbo confirmed

- Reduced NOx emissions

- Diesel-like Drivability

- Simplifications to the Engine Aftertreatment System

- Reduced fuel consumption

By The Numbers

$11B+

Global Hydrogen Turbocharger Total Addressable Market 2030E

79

Patents Pending or Awarded

8.2M+

Unit Demand for Commercial Vehicle Turbos 2025E

~60%

Reduction in NOx over the Drive Cycle Relative to Competing Turbos

20+

OEMs Actively Evaluating HTT Technology

90%

Component Commonality Across 7.5L–16L Engines

Linamar Partnership Provides Necessary Manufacturing Capabilities to Meet Global Customer Demand

HTT’s partnership with Linamar provides supply chain support for scaling the business to meet global customer demand

Overview of Partnership with Linamar

- HTT executed a supply agreement with Linamar, a multi-billion-dollar global vehicle parts company, in September 2021 to manufacture its products–as SuperTurbo’s production volumes increase, Linamar will assume supply chain management responsibilities

- Linamar has 60+ manufacturing locations worldwide, 27,000+ employees and with ~$6.5B of sales is one of the Top 100 automotive suppliers globally

- The Company is working with McLaren Engineering in Livonia, MI to develop the low-volume manufacturing and test process for eventual migration to a high-volume Linamar facility–Linamar’s extensive manufacturing system allow for the transfer of production from McLaren to a high-volume factory